01/26/26

Diesel, Gelling, Anti-gel, Diesel Treat, Diesel Lifeline

By Rich Guida

If your diesel truck throws a P0087 code during cold weather, you’re not alone. This fault code shows up every winter across Powerstroke, Duramax, and Cummins platforms, often right when temperatures dip low enough to turn untreated diesel fuel into something closer to candle wax.

P0087 means low fuel rail pressure, and while there are multiple possible causes, cold weather introduces a very common culprit: gelled diesel fuel. Understanding why this happens, how to diagnose it, and how to fix it quickly can save you from unnecessary parts replacement, towing bills, or downtime.

Let’s walk through what’s actually going on.

The P0087 code indicates that the engine control module (ECM) is not seeing the fuel rail pressure it expects. Modern diesel engines rely on extremely high fuel pressure to operate correctly. When pressure drops below a safe threshold, the ECM steps in to protect the engine.

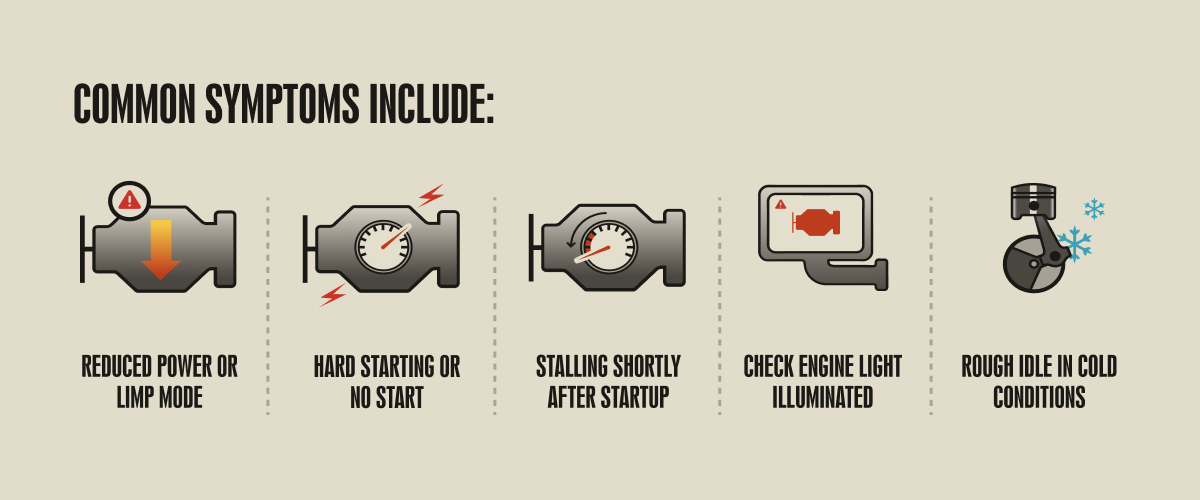

Common symptoms include:

This applies across platforms, including:

While the code doesn’t specify why pressure is low, cold weather narrows the field significantly.

Diesel fuel contains paraffin wax. In warm temperatures, it stays dissolved and invisible. When temperatures drop, that wax begins to crystallize.

Here’s what happens step by step:

This is commonly described as diesel gelling.

The result is the same. The engine is starving for fuel, not because the pump failed, but because fuel can’t physically move through the system.

Before assuming a bad pump or injector issue, look for these cold-weather clues:

In many cases, the truck will run poorly at idle but completely fall on its face under load. That’s classic low fuel rail pressure in cold weather behavior caused by restricted fuel flow.

P0087 frequently sends people down the wrong diagnostic path. Fuel pressure regulators, high pressure pumps, and sensors get replaced when the real issue is upstream.

If fuel cannot reach the pump because it’s gelled or partially frozen, no amount of new hardware will fix the problem.

This is why fixing gelled diesel fuel must come before deeper mechanical diagnostics.

Once diesel fuel has gelled, passive warming alone is often not enough. Gelled fuel won’t return to normal, even if temperatures rise.

To properly ungel a diesel truck, you need a product designed to reliquefy wax crystals and restore fuel flow.

This is the fastest, safest way to un-gel diesel fuel in real-world winter conditions.

Once you’ve lived through a gelled-fuel P0087 event, prevention becomes the obvious move.

That’s where Howes Diesel Treat comes in.

Used regularly, Diesel Treat:

Instead of waiting to learn how to thaw diesel fuel in a parking lot at 10 below zero, treating fuel ahead of time keeps diesel from gelling in the first place.

A P0087 code can feel serious, and sometimes it is. But in cold weather, the simplest explanation is often the correct one.

Gelled diesel fuel restricts flow. Restricted flow drops rail pressure. The ECM reacts exactly as it’s designed to.

Fix the fuel first. Diagnose hardware second.

If you’re seeing a P0087 code in cold weather, especially on a Powerstroke, Duramax, or Cummins, don’t overlook fuel gelling. It’s one of the most common, least understood causes of low rail pressure during winter.

Howes Diesel Lifeline is the right tool to fix gelled diesel fuel when you’re already stuck. Howes Diesel Treat is how you make sure you don’t get stuck again.

Cold weather doesn’t have to mean downtime.